Stoctopus

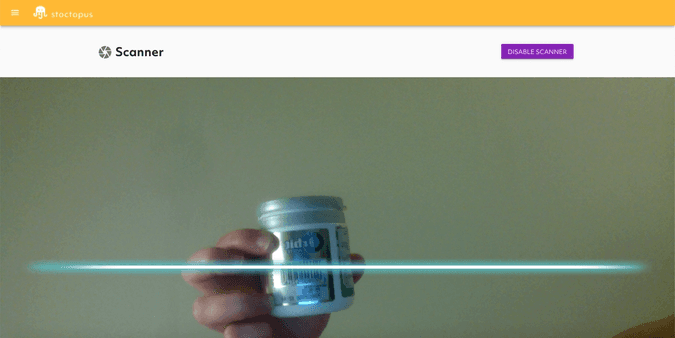

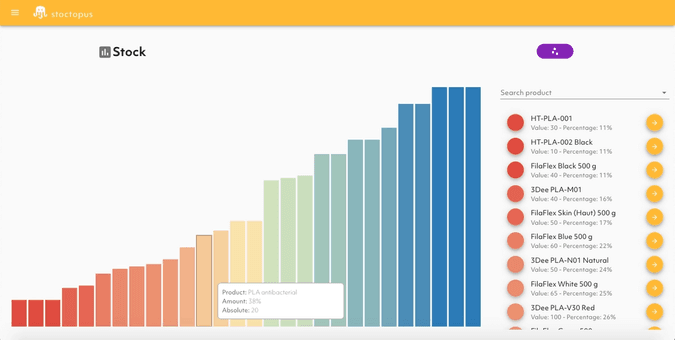

Stoctopus is an intelligent stock management tool for small and medium sized enterprises. The cross-platform application can be used both in a browser and as a mobile app on iOS and Android. A core feature is the scanner, which is able to recognize EAN codes and subsequently gives the user the possibility to either create a new product or log a delivery. Additionally the tool gives an overview of all products, deliveries, stock, user management and company settings. A label printer is also integrated into Stoctopus to print barcodes. Finally, an essential key feature of Stoctopus is the Asset tracking of deliveries using RFID Sensors.

This particular project was implemented in a team of 4 people over the course of 2 semesters during the master program "Interactive Technologies" at the St. Pölten University of Applied Sciences.

I was mostly working on server-side logic of Stoctopus, which meant implementing and maintaining the required REST endpoints. I also kept track of the endpoint changes by keeping an up to date documentation using Postman. Finally I managed the structure of the database and executed necessary changes and improvements in this regard.

The backend of Stoctopus is written in Node.js and Typescript (version 10.10). The server is a simple JSON based REST API that uses a JSON Web Token (JWT) and passport.js for authentication. The data is stored inside a MariaDB database and is processed in the app using sequelize as an Object-Relational-Mapper and migration system.

During the development of this project, we realized that the initially defined target group "Small and medium enterprises" was to vague and not concrete enough. Furthermore, we felt like we were working on a solution without having a specific problem that companies actually face in real life. Therefore, Stoctopus was restructured to fit a specific usecase: the electronics laboratory of the St. Pölten University of Applied Sciences. The final version of Stoctopus then managed the storage facilities of filament used for 3D printers. With the use of RFID sensors, any filament deliveries were tracked, and stored in the system.